Location:Home > News >

CG teach you how to test fiber optic—Special fiber cable ma

CG teach you how to test fiber optic—Special fiber cable manufacturer ChangGuang Knowledge

Objectives: From this lesson you should learn:

What parameters need to be tested

What instruments are used for fiber optic testing

How to perform basic fiber optic testing

Measurement uncertainty in fiber optic testing

How to troubleshoot problems

Fiber Optic Tests

This lesson, another extensive one, is on fiber optic testing. Testing is the most complex part of fiber optics but one of the most important.

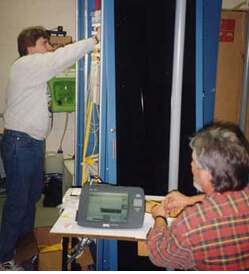

After all fiber optic cables are installed, spliced and terminated, they must be tested. For every fiber optic cable plant, you need to test for continuity and polarity, end-to-end insertion loss and then troubleshoot any problems on every fiber in every cable. If it’s a long outside plant cable with intermediate splices, you will probably want to verify the individual splices with an OTDR test also, since that’s the only way to ensure that each splice is good. If you are the network user, you may also be interested in testing transmitter and receiver power, as power is the measurement that tells you whether the system is operating properly.

Testing involves visual inspection of terminations with a microscope, tracing fibers visually and finding faults, measuring optical power and loss with power meters and light sources and sometimes specialized testing with OTDRs and testers for special issues in long distance links. With this lesson, it's important to learn what needs testing and why, what are the potential errors involved in the tests and where certain tests are appropriate. For example, all installed cable plants require insertion loss testing but some may also need OTDR tests, but OTDR tests are generally not appropriate for short cables and always require a knowledgeable operator to interpret traces - they are not "push button" testers!

Get in Touch

+86-21-3996-3837

alex@changguangchina.com

+86-15216725374